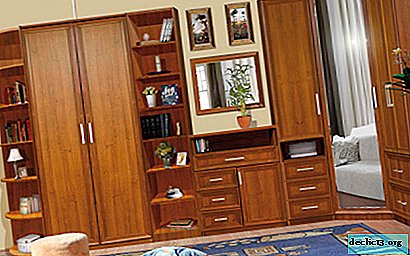

Features of chipboard furniture, selection tips

Chipboard is one of the types of material for furniture production. In practice, 80% of cabinet furniture is made of it, and today furniture from chipboard is in every house. Various options of economy class and more expensive copies of this material solve everyday problems in our homes. And if so, then it is better to learn about this material, its features and scope.

Advantages and disadvantages

All materials have pros and cons. Before you understand this issue, you need to decide what is chipboard. In fact, these chipboards are made from coarse hot-pressed chips that bind the fibers to formaldehyde resins. The surface of the material is covered with a film produced with the participation of thermosetting polymers.

Materials such as chipboard chipboard in the photo are used to design furniture cases. Its advantages include:

- low cost.

- ease of processing:

- Chipboard cut;

- an edge is applied to the ends.

- high strength, long service life;

- lack of negative changes;

- rich palette of colors;

- simplicity in leaving.

The lamination coating provides moisture resistance to the furniture made of chipboard. The reason for the high resistance to moisture is:

- the presence of special impregnation in the composition of wood fibers, which prevents the swelling of the plates from moisture;

- processing the material with a paraffin emulsion.

With the positive properties of the material, you should know what is harmful furniture from chipboard. Like any material, chipboard has disadvantages:

- the main disadvantages of chipboard include the presence of formaldehyde resins. At high concentrations, they have a negative effect on health. In this regard, it is unacceptable to use plates that do not have edges;

- penetration of moisture into the plate leads to swelling. Therefore, all ends of the plates must be coated with PVC or melamine edge.

Chipboard

Chipboard Chipboard with decorative coating

Chipboard with decorative coatingVarieties

The material only at first glance seems to be of the same type. In fact, the types of furniture have differences in composition and quality. The following technical characteristics are included in the classification of chipboard:

- amount and type of impurities;

- construction;

- processing level;

- condition of the outer layer;

- variety;

- mark.

LDSP has the following types of construction:

- single layer;

- multilayer;

- three layer.

Resistance to high humidity, deformation, strength are the criteria for division into brands:

- P-A;

- P-B.

They are different in appearance:

- veneered;

- coated with sulphite and finishing paper;

- laminated;

- not having a decorative coating;

- draft, used for auxiliary works and internal partitions of furniture.

In the classification of the upper layer, the following types are distinguished:

- ordinary;

- coarse-grained;

- with a fine structure.

Products have quality characteristics and are divided into grades:

- the first grade includes material made from selected wood chip material of the same species. Their surface is perfectly smooth. There are no scratches or chips on it. The material on both sides is covered with veneer or a laminating coating;

- for the second grade small surface defects (scratches and chips) are permissible;

- slabs of the third grade have significant flaws on the surface. They are used for auxiliary work.

Chipboards are divided according to the degree of resistance to aggressive environmental influences:

- the product is resistant to moisture, because during the production process it is subjected to special treatment with paraffin emulsion. Wood fibers are impregnated with a special composition that prevents swelling of the material from increased moisture;

- the composition of the material contains flame retardants, preventing its ignition.

Many people who are far from furniture production do not distinguish between wood-based panels (fiberboard, chipboard, MDF). Therefore, the question of which furniture is the best from MDF or chipboard is one of the frequently asked questions. There is a difference, but for an inexperienced eye it is insignificant.

Well-versed in the differences between these two types of plates, craftsmen engaged in furniture production. Only they can judge the properties of materials and what is better, furniture made of MDF or chipboard.

What is the difference between chipboard and MDF? In comparison, it looks like this:

- as for chipboard, for MDF use waste wood, but of smaller sizes;

- instead of formaldehyde resins for the bonding of wood material, paraffin is added, which gives the finished plate such properties as:

- flexibility;

- density;

- environmental friendliness.

When solving this issue, what is better than MDF or chipboard for furniture, you need to take into account the technical characteristics of the materials, their scope. MDF board:

- Smoother than chipboard

- it has the property of deformation, which is used for the manufacture of bent forms;

- paraffin impregnation creates a water-repellent property;

- MDF is used for facades.

Specific tasks are performed by fiberboard. A plate is made of shavings, chips, wood dust by pressing. To bond the material, synthetic resins, rosin, paraffin are added and coated with a laminate. Its thickness reaches about 4 mm. Use fiberboard for the back of the furniture.

Which of the materials is chipboard or MDF is better? Universal is chipboard. It is combined with all furniture materials. If the products are properly used and competently carry out furniture care from the chipboard, it will last a long time.

How to care for furniture to increase its life:

- It should not be allowed that a furniture shelf made of chipboard was loaded over 10-15 kg. This will cause them to deform;

- the use of active detergents is unacceptable, since they can cause significant harm to the protective layer;

- just wipe the furniture while cleaning with a damp cloth.

When assembling furniture with chipboard, the material is the support of structures. A classic option in the manufacture of furniture is the following:

- facade made of MDF;

- from fiberboard - back wall;

- from chipboard furniture case.

It is difficult to judge which material is better when applied in practice, since each of the materials performs its functions. In the construction of furniture, just such an assembly order is adopted and interchangeability is not practiced here.

If the furniture begins to lose its appearance or needs restoration, it is easy to restore furniture from particleboard with your own hands, armed with tools for tinting, varnishing, decorating the facade. As the main materials for restoration you will need: paints, varnish, sandpaper, film, wallpaper, fabric and skillful hands.

Color spectrum

Chipboards are a fertile material from which furniture craftsmen create works of art. There are collections of chipboard decors based on a wide range of colors. Making furniture using design ideas makes LDPS an even more popular type of material. The variety of color solutions is divided into groups:

- plate surfaces decorated with patterns and drawings of extraordinary colors;

- slabs decorated with veneers of various species of trees and flowers;

- glossy decor options;

- coatings imitating rare wood species look interesting and natural:

- "Cordoba";

- merano;

- Oak "Winchester".

- use for coating chipboard standard tones of wood:

- Cherries

- alders;

- beech wood.

- creating a design using solid colors:

- aluminum;

- white.

- Smooth monophonic colors are widely used for coating wood-based panels:

- blue;

- yellow.

The first three groups of colors, given the complexity of the work and the price of the material, are used only for the facade.

What designs are used

Chipboard is widely used in many areas, one of which is the manufacture of furniture. Specialists prefer to work with high-quality chipboard so that their reputation does not suffer, therefore, to create cabinet furniture, this material is carefully selected and purchased only from reputable manufacturers. Chipboard is used for:

- construction and repair work;

- decoration of cultural, commercial facilities, apartments, offices;

- manufacturing functional options for products.

Chipboard is used for the production of cabinet furniture. It is easy to handle, even at home, you can use the necessary set of tools to make furniture from the remnants of chipboard (small shelves, stools), cut any part, remove excess material, and process edges. It is easy to paste, drill, paint. The external design of the plates allows you to use chipboard from creating simple designs with your own hands to samples of elite furniture, where the plate is used not only to create the furniture body, but also for its facade.

Slabs made of chipboard have one more universal property: furniture from them attracts by their accessibility. Using various decorative elements makes it even more attractive.

Selection tips

Choosing chipboard, you need to remember that the material has a laminating film that reliably hides its internal composition. In order not to fall into illiquid assets hidden under a shiny shell, you need to know the criteria for evaluating the material when choosing. Not all grades of plates are suitable for the manufacture of furniture. Therefore, choosing a material, you need to use the following knowledge about assessing product quality:

- no need to buy material at prices lower than peers. There is certainly a reason for this:

- the price is reduced in connection with the action to attract the attention of customers in order to increase customer demand;

- a defective product is offered without explaining the reasons for the price reduction (such a product is suitable for construction work), but not for the manufacture of high-quality cabinet furniture;

- the goods must be carefully inspected for mechanical damage:

- the decorative film should not have scratches and cracks;

- the surface of the plate should be smooth.

- check the condition of the edges of the sheet. If they are thicker than the thickness of the surface, do not buy such material. This indicates its swelling from excessive moisture. Furniture cannot be made of swollen material: fasteners are not held in it.

The main advantage of chipboard is its protection against aggressive environmental influences: high humidity, the influence of pathogens and fungi, rotting, high resistance to temperature, a long service life. If negligence is allowed in the selection and the material has flaws, the protective properties of the material will be violated over time. This will lead to a decrease in the life of the device and a disappointment in the acquisition.

Video

Photo