Recommendations for the manufacture of furniture facades in the home

Important components depend on the facade of the furniture: appearance, functionality and cost of the entire product. The area of parts on the outer front side of cabinet furniture, relative to the entire product, is small. But, despite this, the manufacture of furniture facades requires a lot of time and effort. This is the front side of the structure, each flaw will be striking.

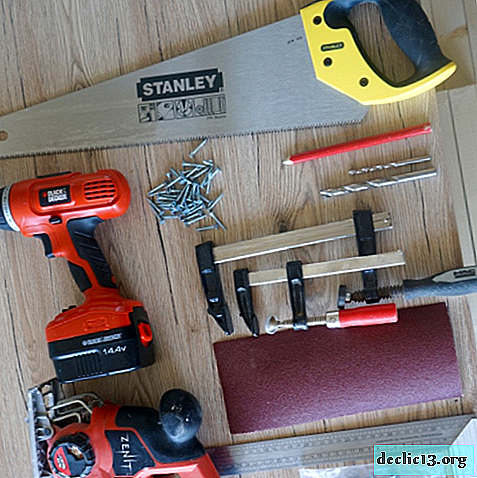

Necessary tools

To independently make a furniture facade that does not differ in quality from the factory product, you need to purchase the necessary tools in advance:

- The boards from which the frames will be sawn - it is important to select elements with a smooth surface, without knots and chips;

- Sheets of plywood, plastic or glass, with a thickness of not more than 6 mm - they are needed to create a panel - an important element of decor;

- A metal ruler with a marking of 30-40 cm;

- Pencil;

- Electric jigsaw with a set of wood files;

- Roulette;

- Joiner's glue;

- Glue brush;

- Disks for cutting boards, it is convenient to use a cutter.

To maintain order during operation, prepare a bucket of water and a rag.

Manufacturing technology

The manufacturing process of furniture facades is complicated. On your own, you can create neat and suitable doors, if you clearly follow the stages of work.

Settlement

The first stage of the technological process is calculations. The dimensions of future doors are easy to make: it is enough to check the parameters of doorways using a tape measure. In order for the calculations to be correct, it is necessary to clarify the details:

- The size of the facade should differ from the height of the opening by 3 mm to the lower side. If the item is not observed, the finished doors will not freely close and open;

- The width parameters of racks and crossbars do not have certain standards. However, their dimensions on the same piece of furniture should be the same;

- The difference in width between the product and the doorway should be 3 mm. If you need to make 2 doors, then you need to carry out the following calculations: divide the width of the opening in half and take away 1.5 mm;

- The length of the crossbar is calculated according to the following scheme: the sum of the width of two racks is subtracted from the width of the facade and 2 cm is added;

- The dimensions of the panels are defined as follows: width - more than the crossbeam by 2 cm, height - width times 2, minus the height of the door and plus 2 cm.

Having figured out the calculations, you can proceed to the selection of materials.

What materials are best suited

The furniture facade is responsible for aesthetics and functionality. Therefore, the doors on cabinets and headsets are given great attention. What material to take as a basis, what to make a panel from, how to decorate and other questions are asked by the masters at the first stages of work. Everyone decides what to choose.

The most common materials for making furniture facades with your own hands:

- Plastic;

- MDF;

- Aluminum;

- Glass;

- Wood.

Each material attracts with its merits and repels flaws. The color of the tree changes under the influence of the sun, and the glass is not affected by sunlight. The glass door may break from impact, and the tree retains its strength for a long time. It is difficult to work with certain materials at home, so only professionals take them to work.

The easiest way to make a furniture facade with your own hands from wood. When using carpentry tools, the material becomes malleable. Less malleable materials - plastic, glass - are used for finishing facades.

Wood

Wood Aluminum

Aluminum Glass

Glass Plastic

Plastic MDF

MDFSawing items

On the basis (board or plastic), the location parameters of the crossbars and racks are noted. Then the details are sawn. Columns are made in double quantity. After that, special grooves need to be cut out on the crossbars, through which they will be fastened together. At the end, each part must be carefully sanded.

In order for the panels to stand firmly in place, special grooves need to be cut. Using the prepared discs, it is necessary to cut holes with a width of 5 mm and a depth of -10 mm. Before cutting through the grooves, you need to check the disk for performance on the waste material, so as not to spoil the quality workpieces.

Having ready-made parts on hand, you can start assembling. The process consists of two steps:

- Racks are inserted into the cuts on the panel;

- On the top and bottom, the crossbars are fixed.

All structural details should fit together perfectly. If inconsistencies appear during assembly, they must be removed with sandpaper.

Do the markup

Do the markup We saw material

We saw material Grind the surface

Grind the surface Cut the grooves

Cut the grooves Make a notch

Make a notch Connect the elements

Connect the elements We clean sandpaper

We clean sandpaperFinish

Facade decoration depends on the desires and capabilities of the person. Most often, three options are used in the manufacture of facades.

| Material | Description |

| Solid wood | This option is considered classic and is used for decoration of furniture of any type (for the kitchen, bedroom, living room). Usually he is chosen in the case when the furniture must correspond to one of the expensive styles - Empire, Baroque, Classicism. To reduce the price of the facade, you can make the base of MDF, and close the front part with solid wood. Such doors will look good on classic or modern furniture. |

| Painted MDF | Smooth and bright facades are most often used in the creation of kitchen sets and wardrobes. Glossy panels will look equally good in modern style or futuristic design. They can not be attributed to cheap options, but they do not differ in practicality either: the smallest spots immediately become noticeable, chips and scratches are formed with minor impacts. If you want to have original and bright furniture, then this option is best suited. |

| Aluminum facades | Aluminum is used as the frame. To fill the space, plates made of MDF, glass or plastic are installed. The option is not the cheapest, but very practical. The advantage of such facades is a neat appearance and durability. Keeping such facades clean is simple: just wipe it with a damp cloth and detergent from time to time. Similarly, furniture is often adorned in different styles. For minimalism, it will be enough to make inserts of glass or transparent plastic. The same option will fit into the loft style. For kitchen sets, facades use glass. For Art Nouveau, plastic of bright colors is more suitable. |

There are other, less popular types of facade decoration. Not all of them fit into the usual interior, so they are considered to be non-standard. The combination of different materials to create the facade of the furniture - the choice of originals. This may include various variations with MDF, which is taken as a basis. Glass and plastic are taken as an addition. Often the facade is entirely made of wood material, and decorative film is used as protection and decoration.

Solid wood

Solid wood MDF

MDF Aluminum

AluminumVarnishing and painting

Before painting, you need to prepare all the materials. It is recommended to paint over facades with a brush. If you plan to use a spray can or spray gun in the decoration process for furniture, then you need to pre-cover the nearby objects with a film so as not to stain them with paint.

The staining workflow consists of several stages:

- Surface cleaning from dust and small debris;

- Degreasing with alcohol;

- Putty. This stage is not always necessary, but only if there are chips and bumps on the facade;

- Primer. Each material uses its own grout. You can apply it with a brush or aerosol. To increase efficiency, at least two layers must be applied;

- Application of paint. To prevent gaps on the surface, apply 2-3 coats.

Painted surfaces will look more spectacular if coated with glizal. The composition must be diluted with water according to the instructions and put with a clean brush on the facade. For a mirror finish and longer service life, painted doors are coated with several layers of varnish. Before applying, wait time for the paint to dry.

To obtain glossy facades, acrylic varnish is used. It is applied in two cases: after painting and instead of paint. If it is planned to leave the natural color of the base material for the facade, then it must be varnished. It is usually used for wooden surfaces. Varnish improves the appearance of furniture, increases strength and prolongs its service life.

Before varnish it is necessary to put a primer layer on the surface of the facade. After that, irregularities are smeared with putty. When the surface dries, you need to sand it with an emery cloth. After which a primer layer is applied again. The last step is to apply the varnish with a brush to the joints of the facade and the main part. To obtain a mirror surface you need to cover it with varnish in several layers. At least 5 hours should pass before each coating.

We clear a covering

We clear a covering Apply primer

Apply primer Close up cracks putty

Close up cracks putty Degrease with alcohol

Degrease with alcohol Paint the surface

Paint the surfaceCreate beautiful inserts

In the manufacture of furniture facades, you can turn on imagination and create a unique design. There are several options for making facades beautiful and unusual.

- Combination - fromYou can make an insert into the facade of furniture from any material. Combining two dissimilar materials, you can get a unique style. It is important to understand that unusual materials on the facades should be at least a little in harmony with the decor of the room. Most often combine wood and textiles, plastic and aluminum, leather and glass. Bamboo and rattan inserts look very unusual, but beautiful;

- Drawings are an original way of decorating the facade of furniture. It is suitable if the insert on the door is glass or plastic. You can draw by various means, but most often acrylic paints are used. With their help, you can draw anything you want. For accuracy, you can apply a stencil. After complete drying, the patterned surface can be washed with water and detergents. The manufacture of furniture facades has become very popular, so new ways of decor are being created. Sandblasting is one of the last. At home, creating something like this is difficult, because the process requires special equipment. As a result, a neat matte pattern appears on the mirror surface. If there is no desire and ability to draw, then a self-adhesive film can be glued over a glossy surface. You can also use ready-made stickers for furniture;

- Stained-glass windows and mosaics - do-it-yourself furniture facades look very beautiful and expensive, with glass used as inserts. By showing imagination and patience, you can create an original design. This will require several multi-colored sheets of glass, a glue gun and a glass cutter. In the process, it is necessary to cut the glass into pieces so that when sticking to the facade there are no gaps between them. And if you really try, then from small parts on the surface of the facade you can create a small picture according to the type of mosaic.

Having shown imagination, perseverance and accuracy, you can independently create furniture that will look more beautiful than models from magazines. The main thing is to think through the project well and select all the necessary materials for color and texture.

Leather inserts

Leather inserts Drawings

Drawings Mosaic

Mosaic